NEWS

Application and characteristics of ceramic nozzles

Release time:

2022-04-08

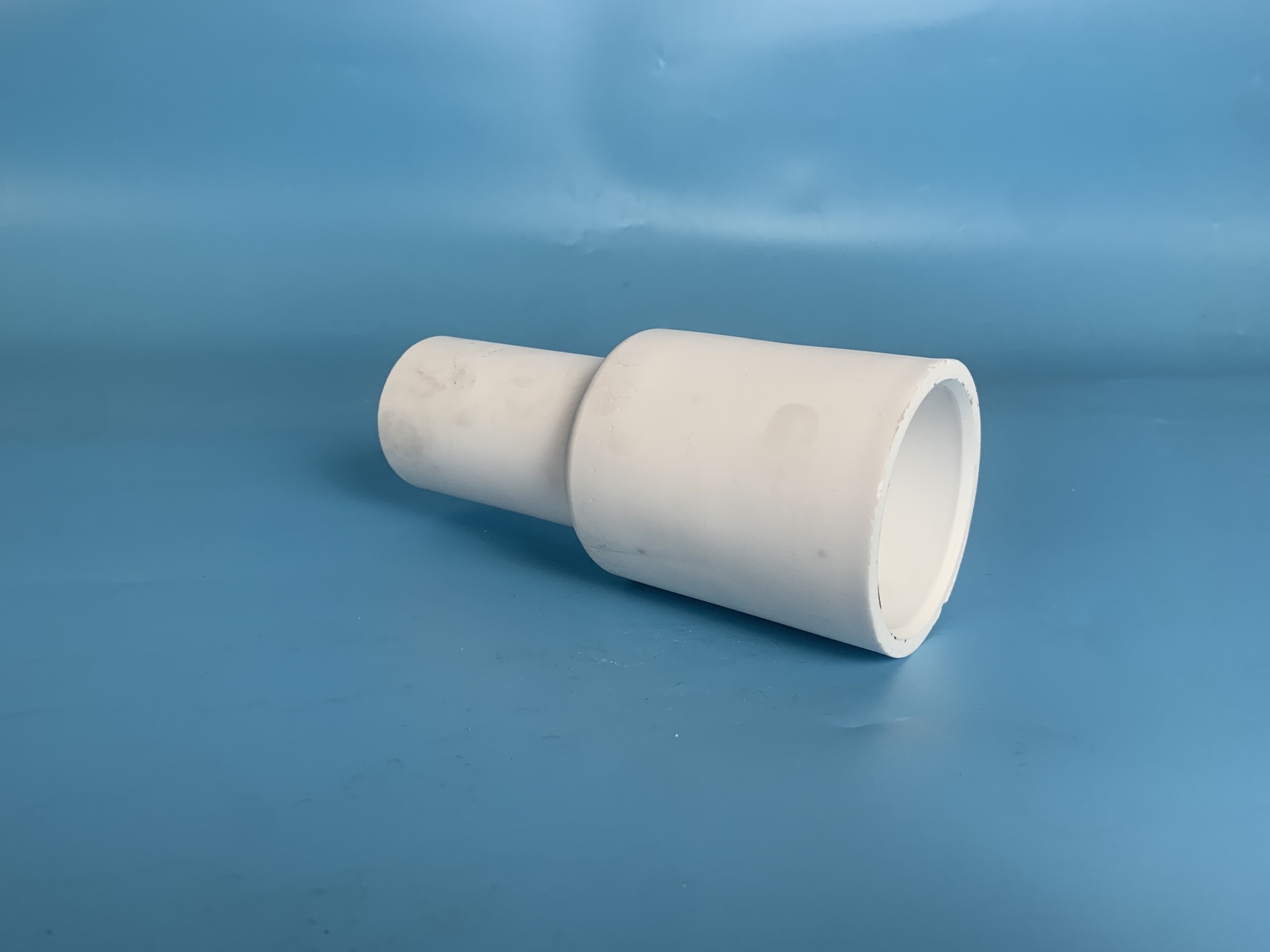

In a variety of spraying, spraying, oil spraying, and sandblasting equipment, ceramic nozzles are key components, even the main components. For example, sprinkler irrigation equipment in agriculture is more common.

According to material classification, nozzles can be divided into metal nozzles, plastic nozzles, ceramic nozzles and alloy nozzles. Here we will focus on introducing ceramic nozzles.

First, the characteristics of ceramic nozzles

Compared with nozzles made of other materials, ceramic nozzles have outstanding features and advantages.

1. Corrosion resistance

The chemical resistance of ceramic nozzles is very good. When in contact with acid and alkali substances or chemical substances for a long time, generally no chemical reaction will occur, and the service life is long. Nozzles made of other materials are prone to oxidation or corrosion and need to be replaced frequently. Therefore, ceramic nozzles are often used to spray chemicals.

2. Wear resistance

Compared with plastic nozzles, ceramic nozzles have better wear resistance. The hardness of ceramic material is 266 times that of manganese steel and 171.5 times that of chromium cast iron. It has certain impact resistance and will not be easily deformed like ceramic nozzles. The effect of wear and tear during use is also very small, and excessive damage will not occur in a short period of time.

3. No rust

Compared with metal nozzles, ceramic nozzles are not easy to rust when exposed to water in time. The biggest disadvantage of metal nozzles is that they are prone to rust. Once it gets wet, if it is not maintained in time, it will rust after a long time, and there is no need to worry about this situation with ceramic nozzles.

Second, the application of ceramic nozzles

Based on the performance characteristics of ceramic nozzles, they can be widely used in these industries.

1. Agricultural irrigation

Ceramic nozzles can be applied to agricultural production, changing the traditional irrigation mode, reducing the frequency of equipment replacement and saving costs.

2. Spray

Ceramic nozzles can also be used in phosphating, passivation, degreasing and other operations on the surface of metal parts. Can paint on metal parts and work in high temperature environment.

3. Humidification

Ceramic nozzles can also be used for humidification in factories, warehouses, textile workshops, printing factories and other places. By regularly sprinkling water in these places, static electricity can be effectively generated, thereby reducing fire accidents caused by static electricity in these places.

Recommend