NEWS

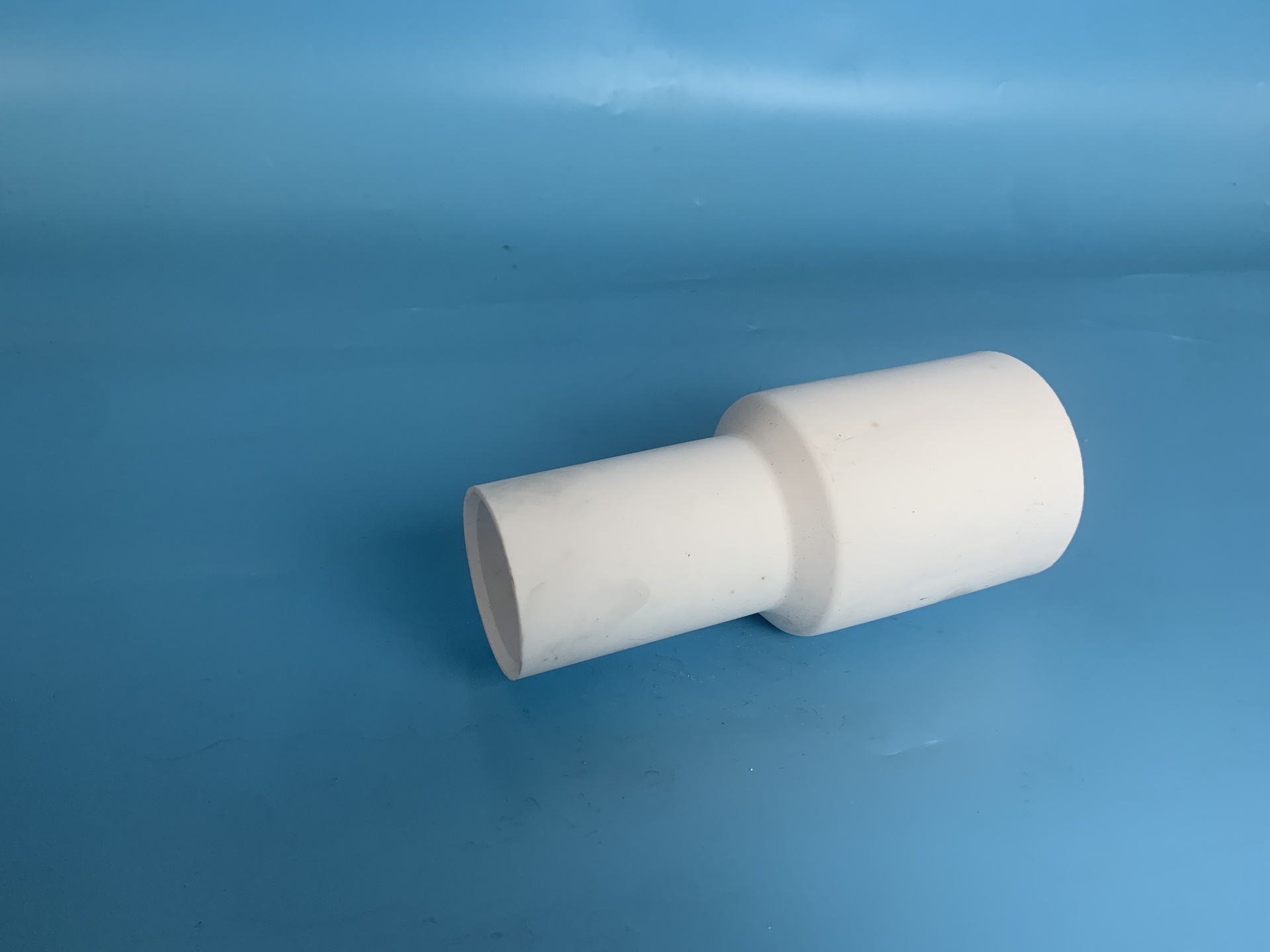

Plastic Nozzles Versus Ceramic Nozzles: When To Use On A Machine?

Release time:

2022-03-24

Spraying technology has evolved over time, and just as people use rags, brushes, and brooms to dust their feathers, technological advances have brought new tools that make operations safer, easier, and more effective. Today, the manufacturing technology of nozzles is becoming more and more complex. But: Which is better, a plastic nozzle or a ceramic nozzle ? Using different nozzles can have a big impact on spray results and running costs. Therefore, we have prepared this article so that you can better understand the characteristics of nozzle materials and know how to choose nozzles for different crops.

What are the characteristics of plastic nozzles? Plastic nozzles are made of polymers with high wear resistance. In order to make its structure correct and ensure good distribution and flow, high-precision molds must be used in manufacturing. This material is cheaper in price than ceramic and stainless steel models. At the same time, plastic nozzles are more easily damaged than ceramic nozzles. However, with the development of technology, the service life of this polymer can be as long as that of stainless steel products, which means that its service life can meet the needs of daily operations.

What about ceramic nozzles ? Ceramic nozzles are very strong, that is, they are very durable. They are made of aluminum oxide, a highly wear-resistant material. A high-quality ceramic nozzle whose structure is 99% made of aluminum oxide for extra hardness. Based on these characteristics, ceramic materials are more expensive, but can maintain excellent spraying performance for a long time.

What is the main difference between the two? 1. Durability: Among all materials, ceramic nozzles are very strong in the market, more durable than stainless steel and brass. So if you use stainless steel, plastic or brass nozzles, they can maintain good performance early on, but in the long run, wear can be severe and spray performance will be reduced. 2. The difference in durability of different materials: the service life of plastic and stainless steel is about 6 times that of brass; the durability of ceramics is 20 to 50 times that of brass. It is also worth noting that the cleaning process also has an effect on the durability of the nozzle. For example, using metal materials to clear clogs will increase the wear of the nozzle. 3. Working pressure: The ceramic nozzle can withstand a large working pressure, up to 300 pounds per gallon. On the other hand, plastic and stainless steel nozzles are less than 100 lbf/pol. This factor is very important because operating pressure affects droplet size and application volume and needs to be adjusted during operation.

How to choose a nozzle? The choice of nozzle depends on the pesticide product used and the durability you want. Ceramic nozzles are very durable and generally have a wider range of applications. Although the initial cost is higher, it is more cost-effective in the long run. For example, when the chemical liquid is highly corrosive or the liquid particles are large, ceramic nozzles are more suitable. It is also suitable for nebulizers with higher frequency and higher working pressure. But remember a basic guideline: the stronger the material, the longer it will retain its spray characteristics, such as distribution, droplet size and flow rate. On the other hand, if farmers are spraying less frequently and with lower pressure for short periods of time, they may consider using plastic nozzles.

Recommend