NEWS

Let's talk together: silicon nitride ceramic substrate

Release time:

2021-12-01

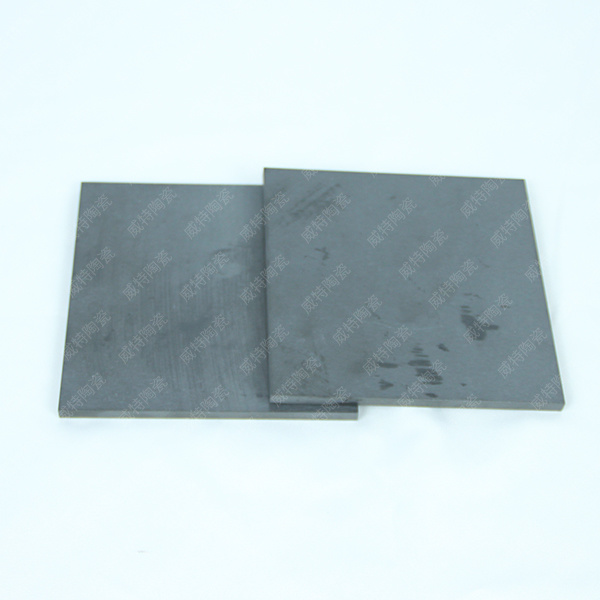

Silicon nitride ceramics are widely used in many industrial fields, and ceramic substrates are also commonly used in the industry. Let's talk about silicon nitride ceramic substrates together.

From the perspective of element composition, it is a silicon nitride ceramic sheet sintered by adding a small amount of oxide and rare earth to silicon nitride powder synthesized by silicon and nitrogen .

From the perspective of element composition, it is a silicon nitride ceramic sheet sintered by adding a small amount of oxide and rare earth to silicon nitride powder synthesized by silicon and nitrogen .

From the perspective of substrate application, it is one of the key materials for power electronic devices, and it is mainly responsible for two main tasks of insulation and heat dissipation.

Judging from the perception of the difficulty of the project, only the United States and Japan have entered the stage of industrial production. Not only are the prices high, but they are not sold to us. Because this is a dual-use product.

From the perspective of "new infrastructure", it can be said that almost all high-power power supply equipment is needed for 5G base stations, rail transit, new energy vehicles, wind power, and solar inverters.

Anyone with middle school chemistry knowledge knows that nitrogen and silicon have a huge storage capacity on the earth, and the material composed of these two elements is silicon nitride, Si 3 N 4 .

Modern functional ceramics made of silicon nitride as the main material have extremely wide applications. Here, we just talk about silicon nitride special ceramics from the perspective of circuit substrates.

Circuit substrate: The past cognition is that the circuit combination of separate components or the circuit combination of integrated circuits and discrete components forms a flat material that meets the functional requirements of the overall circuit. The circuit substrate is made of two functional materials, insulating and conductive. Single-sided printed circuit board is the original form of circuit substrate.

Power ceramic circuit substrate: unpackaged power devices can be directly mounted on the power ceramic circuit substrate, and then packaged. The purpose is to reduce the thermal resistance of power devices, and the direct effect is to reduce the operating temperature of power devices and increase power and reliability. As one of the basic industries developed in the fields of information, transportation, aerospace, and industrial automation, power electronics technology is a technology that uses electronic devices to convert and control electrical energy. The development direction of power electronic devices is: small size, high density, high current, high power, low power consumption, which is the core device of electronic control and power conversion. Widely used in electric vehicles, rail transit, photovoltaic inverters, wind power generation, smart grids, large-scale industrial electrical frequency conversion and servo control, and also has a wide range of applications in aerospace and military electronic technology. Silicon nitride ceramic circuit substrate is one of the key materials for manufacturing power electronic devices.

Everyone in the industry knows that China's integrated circuit industry has made great progress in the past year, and this achievement has not come easily. In the face of adversity, China's integrated circuit industry has embarked on a development path that suits itself on a tortuous road, and it has made up for one of the most important links in China's industrial chain.

In the entire integrated circuit family, large-scale integrated circuits, low-power integrated circuits and discrete devices are important components of this family; contemporary, electronic power devices and electronic power integrated circuits are developing with the rapid development of industrial automation, the third generation of semiconductor materials The industrialized development of the integrated circuit industry has become an important part of the integrated circuit industry, and it is also affecting the technological progress and development of more industries.

For example: high-speed rail, new energy vehicles, high-end machine tool drives, wind power generation, solar power generation and various automation equipment all require electronic power integrated circuits to drive, which is a large market worth more than 100 billion yuan.

In this large market, power integrated circuit ceramic substrates are key materials for carrying semiconductor power devices. In the past two years, third-generation semiconductor materials such as gallium nitride and silicon carbide have been vigorously developed in my country. It is necessary to use third-generation semiconductor materials to produce high-power semiconductor devices. If there is no power integrated circuit ceramic substrate, the heat dissipation effect of semiconductor devices It will greatly reduce and reduce the use effect of the device. Since power integrated circuit ceramic substrates are indispensable for the development of power electronics technology, they have become one of the key materials in the semiconductor industry for which Western developed countries have imposed an all-round technical blockade on our country.

Recommend